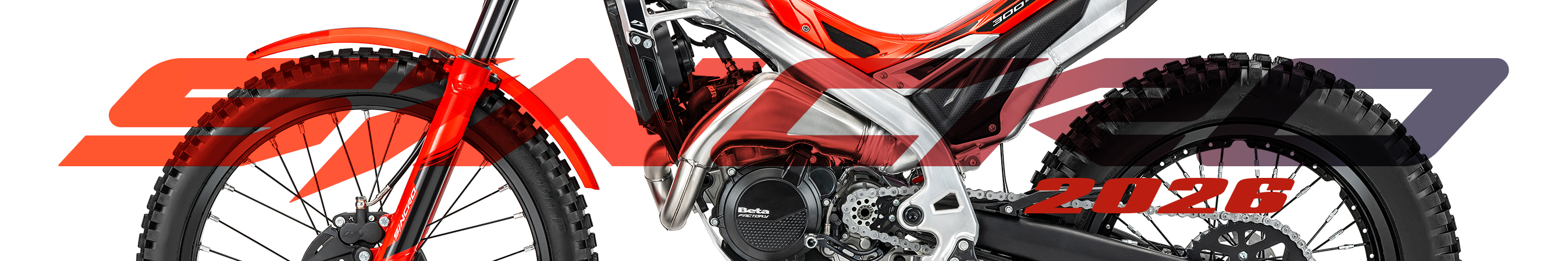

Beta presents the new SINCRO MY 2026

For many years, Beta has been the leader in trial technology, competing at the highest level in different countries with different level of riders. Since 2009, the EVO model has help carry these riders to many victories. Today, The Evo name has been retired to make way for the all-new Sincro! A new generation of trial motorcycles that represent years of development that included some of the top-level riders as well as Novice riders, working with Beta engineers to create an All-New platform for the Beta brand.

The new Sincro was born with an ambitious goal: to create the perfect SINCROny between rider and bike, a human-machine bond never experienced before, so deep as to transform every gesture into a pure expression of control and smoothness.

More than in any other discipline, precision and sensitivity are paramount in trial. Power or lightness are not enough: you need control. Beta pilots and technicians know this very well and have worked years to bring the RideAbility concept to the next level in trial. This bike surpasses the EVO project, by truly interacting with the rider, ‘feeling’ them and reacting naturally, anticipating their intentions. The true performance potential is hidden in this symbiotic relationship. If the rider no longer has to worry about the bike’s reactions and can experience it as an extension of their body, any obstacle becomes a challenge to face with clear thinking and style. Frame, suspension, weight distribution, engine response: every element has been redesigned to encourage an instinctive and immediate interaction.

With this new launch, the Beta Trial family remains one of the most extensive on the market, with six different models, all with their own personality that meet the varied needs of all riders.

SINCRO 300 2Str

It confirms itself as the best bike for riders looking for an agile and easily controllable 2-stroke, with a more docile temperament and with slightly less power and torque than the range-topping model. The SINCRO 250cc is ideal for the amateur looking for class-beating performance combined with precisely manageable power and impeccable rideability.

In line with the Brand’s values, the engineers updated the frame along the lines of a specific philosophy, to improve its handling, centralizing its weight to recreate a feeling of complete adherence to the hand’s motion and the rider’s needs, and the engine, to improve its handling at low speeds and the overall performance.The new SINCRO is the result of a complete redesign, in terms of suspension and engine alike.

To uncover all the project’s new features, as revealed the public at the Trial Des Nations 2025 in Tolmezzo (UD), we will go over the 300 2Str displacement, postponing the presentation of further details on the remaining displacement at the EICMA.

New SINCRO 300 2Str features:

Frame:

All-New design while retaining Beta’s signature aluminum backbone design that riders have come accustomed to. The integrated fuel tank allows for the tightest of turns while at the same time, providing a smooth and precise feeling. This new frame has updated geometry as well as new front and rear forgings.

Concerning the bike dynamic operation, the first feature that deserves to be mentioned as a characterising element in Beta Trial models is the aluminium alloy hydroformed backbone frame.

This structure gives the smoothness and driveability so much appreciated over time by riders in every category. Beta decided to keep the hydroforming technology in the frame with an integrated tank - a signature component of the Tuscan company - and came up with a completely new design layout and size.

Whilst maintaining the construction solution of the main beam, which traditionally houses the integrated tank, the frame has been completely updated. The geometry has changed, as well as the new front and rear forged elements in strategic locations that improve overall handling while in sections. The new frame was reinforced in the steering tube area, to strengthen the structure, reducing welds and connecting everything to the front forged element on the frame. The radiator now has a new fixing system and is anchored to new arms, also forged. As expected, a level of quality only Beta can provide.

The engine maintains its function as a structural element, but the fixing points to the frame have been changed. The result is an increased flexural and torsional stiffness compared to the previous EVO generation.

The SINCRO project has moved in the direction of creating an even leaner bike than Beta’s previous Trial generation, reducing the vehicle overall dimensions and weight, to achieve class-leading performance and manoeuvrability.

Additional changes are the attachment of the rear shock, moved farther forward at the top mount, this along with new linkage mounts further refines the response of the rear suspension and reduces rider fatigue while riding over rocks. The steering angle is also more open than in the past, and this, together with the changes made to the rear shock, has provide one of the best rear suspension system in trial.

Swingarm & Suspension:

Along with the frame, an all-new swingarm has been developed to match the style and performance of the frame. The swing arm’s weight has been reduced by 100 grams thanks to the new layout and the material processing system by tube swaging and subsequent mechanical forming by means of moulds, the swingarm is at the same time lighter and stronger, with a lot less welds than in the past in reinforcement points under stress. The variable diameter of the swingarm also adds to the overall refined handling.

From the suspension side, the interventions on the new SINCRO were decisive in achieving the goal that the technicians and riders had set themselves which was at a high standard. Both fork and single shock absorber have undergone significant updates, to improve the ability to overcome obstacles and always obtain an optimal response to the rider's impulses.

Other Chassis:

Some of the other elements on which the technicians have worked to create a winning package for the new SINCRO include:

The new suspension and structural components are harmoniously integrated from an aesthetic point of view by an all-new set of bodywork, which lend the bike a slender appearance, better connecting all the components, while remaining slim and minimally invasive. The smaller size has a lower effect on the bike’s movement, even though the surface is big enough to accommodate new appealing graphics.

Taking up the legacy of the previous model, the tank cover area houses the maps switch button inside a new lid obtained by co-moulding - a construction technique that ensures solidity and excellent aesthetic performance.

Engine:

The previous generation of Beta Trial bikes has been firmly at the top of competitions around the world for years, and for this to remain true, the Tuscan company has decided to go in an entirely different direction with the new SINCRO, and the engine is no exception.

The engine design is completely new. The only things maintained by Factory Racing Beta Department engineers were the bore and stroke measurements, which remain 79x60.5mm (300 2Str). Everything else has been revolutionised compared to the past EVO models. Aesthetically, the first thing that catches the eye when looking at the new SINCRO, are the new motor crankcases, with the kick starter on the right, and the chain drive on the left.

The project was focused on the objective of moving rotating masses toward the centre, to improve the Sincro’s handling, regardless of any obstacle. To achieve never-before-experienced RideAbility, the flywheel diameter, weight and inertia have been reduced, while those of the crankshaft have been increased. The crankshaft/swingarm pivot axis has been reduced by 2 mm.

The cylinder is new, both externally and in the internal transfer port geometry, where all the feed and discharge flows have been carefully reviewed, through precise analysis. The intake system is one of the elements that most breaks away from the past. Now the intake is located directly in the cylinder, with a coupling without intermediate passages. This moves the reed valve pack closer to the cylinder barrel, the area where the pressure pulse generated by the movement of the piston starts. In this configuration, the connection from the carburettor to the reed valve becomes very short and bypasses the upper petal. This anticipates the reed valve opening, making the best use of the resonance waves created inside the cylinder and the crankcase when the discharge, transfer and suction lights are opened simultaneously. The result is a faster engine, with a more precise reaction to the throttle command.

The result of this new intake design is felt directly at the throttle as the response from the engine is instant. This enables the rider to become more “at one” with the bike and the traction that is needed. Other advantages include less “power pulses” from the engine at idle or lower speeds while at the same time, offers an improved fuel/oil burn which makes the engine run cleaner.

Other big news about the new Sincro is the ability to install an electric start system as an accessory item. (not available on the 125cc). This component is provided as Kit Factory part and does not involve any aesthetic modification to the crankcase covers if the installation is carried out at a later time. The battery that powers the kit is housed behind the headlight mask. This will allow Beta riders to choose between E start or traditional kick start only.

The new cylinder head is now made of a single block, and the crankcase covers have also been redesigned with new internal geometries and an aesthetic impact in lines with all the new bike shapes. To contain weight, they are made of a magnesium alloy.

As for the exhaust, the new SINCRO 2Str maintains the characteristic expansion of the manifold, but this has been redesigned to match the performance of the new engine, guaranteeing benchmark performance. The silencer has been tuned accordingly, at both a functional and aesthetic level.

Engine cooling circuit:

The entire cooling system has been redesigned with a rationalised layout, fully integrated into the engine without external piping. The radiator is more compact than in the past, even though it has maintained the same heat exchange ability by the redesign of the tray. Another new feature is the option of tilting the radiator on the two lower fixing pins. By unscrewing a knob that holds the radiator firmly anchored at the top, the upper tray can move forward, uncovering the cap. This mechanism has many advantages, both from an aesthetic and functional point of view, and prevents breakages caused by accidental impacts or falls. By keeping the cap hidden, only the flat heat exchange surface is visible, preventing any collision from ruining a delicate point such as the liquid top-up.

The water pump and the cooling liquid passages have also undergo a thorough study, using a constructive solution that allows to have no cooling fluid in contact with the internal clutch cover, despite not having external piping passages. This is possible thanks to a nylon insert mounted internally to the clutch half-shell that creates a connection duct between the water pump outlet and the cylinder inlet. The new centrifugal pump - less cumbersome than the one equipped in previous-generation models - was specifically designed to push the cooling liquid through isolated passages inside the crankcase (instead of the external tubes) and takes advantage of a different spiral section of the pump body and a closed impeller, which guarantee greater efficiency.

Clutch & Transmission:

The lower part of the engine has also undergone radical updates, with a new geometry and a more compact six speed gearbox. The primary transmission ratio has changed mesh perfectly with the new engine and transmission. The clutch is also All-New as it uses diaphragm springs (instead of helical springs) also present on the Beta Enduro range, with dedicated sizing and components. The quantity of clutch discs is the same number as in the previous generation, even though they have a smaller diameter and a different material than in the past, making it possible to maintain a more compact clutch pack and crankcase. Despite its small size, the clutch maintains an optimal behaviour under stress, keeping the drive control softer, more modular and precise, tiring the rider considerably less. Both engagement and disengagement have been improved, while the clutch is now capable of transmitting even more torque. Moreover, to allow for totally customisable set-up, three different spring preload settings are now available, adjustable with a simple mechanical procedure. To ensure optimal manageability even when employed by Pro riders, the new clutch actuator is now designed with a system that always keeps its piston at the optimal pressure, thanks to the use of a specific spring. This component upgrade allows the rider to put more demand on the clutch without losing performance.

The result of this complete redesign is a much more compact engine, with almost 800g of weight shaved off compared to the previous generation. From a performance standpoint, the range of use has been significantly increased, and its handling and sharpness at low speeds are much improved compared to the past, while maintaining top performances.